As a packaging converter, you’re undoubtedly familiar with the daily concerns and workplace pain points shared by packaging industry professionals. In recent years, the industry has faced both global and market-specific challenges demanding innovative solutions to ensure success today and sustainable growth in the future.

In this blog, we’ll address key challenges packaging converters face and highlight how a graphic editor can help you work faster, smarter, and more efficiently—without compromising quality.

More, but Shorter Print Runs & Lead Times

Brands continue to create additional variants of product packaging to improve, update, and personalize their offerings, as well as compete with seasonal trends and maintain regulatory compliance.

More SKUs means more jobs for packaging converters, with less time to get each job out the door. There’s only so much your team can achieve without sacrificing quality and overlooking errors.

Jobs are also becoming smaller as brands are storing less packaging. Essentially, you must do more, in less time, without jeopardizing your quality standards.

Environmental Sustainability

It’s no secret that today’s consumers place great importance on environmental sustainability. They care about who makes their product, what’s in it, and how it’s packaged. When they’re shopping, they’re making choices based on which packaging is more sustainable and least harmful to the planet. They also want to know if the brand they’re buying from (and its supply chain) is working sustainably as a whole.

Of course, the packaging still needs to look amazing to increase sales and provide the standard consumers have come to expect.

Clearly, reducing environmental impact should be an urgent focus of your business. And there are many ways to do this.

Shortage of (Skilled) Labor

For reasons everyone knows, since the early 2020’s, it has been difficult to find, train, and retain good staff.

These effects are still being felt across the packaging industry. To combat this challenge – upskilling staff at speed is imperative. Even more vital is allocating existing resources sensibly, such as eliminating wasteful processes that don’t add value yet require a lot of operator effort.

Remote Working and Multi-Site Production

Remote work is more prevalent than ever.

However, today, many companies are not using the right software systems or processes to enable seamless collaboration among teams. This disconnect leads to increased errors and their resulting costs.

It’s imperative to provide employees with access to jobs and data across multiple locations.

When implemented correctly, the right solutions make it possible for team members and stakeholders to work on projects anywhere, anytime, thus changing the way we all work forever.

Global, Political, and Social Instability

The reasons for world instability are far beyond the scope of this blog. However, this is not to say they don’t have an impact on the packaging industry.

Whether it’s rising fuel and transportation costs, trading sanctions, travel bans, or unease among colleagues, there are many issues to consider and find solutions for.

Clearly, we must all be attentive to recognizing and adapting to such issues and developing the agility to respond to them.

How A Graphic Editor Can Help

Now that we’ve identified the challenges, let’s talk about the solution.

A graphic editor enables operators to work faster and smarter – and to focus their time where it really makes an impact – rather than on low value, time-consuming tasks.

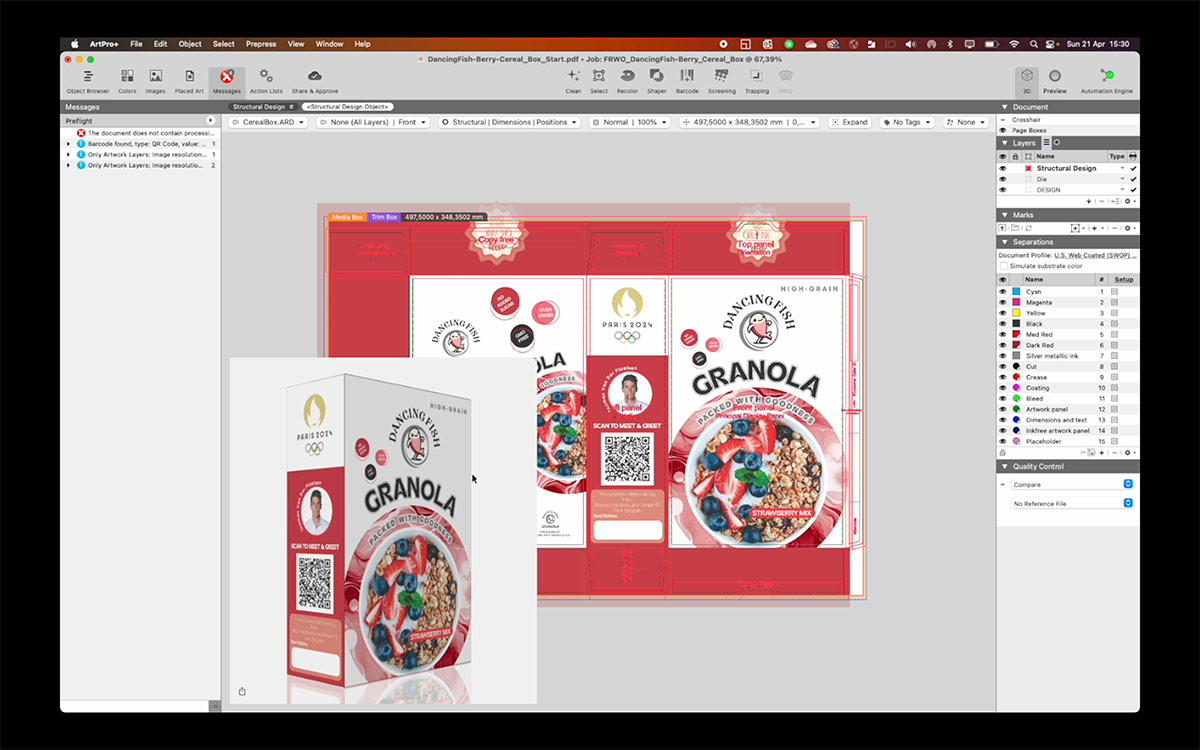

ArtPro+, Esko’s graphic editor, targets the core challenges faced by both prepress suppliers and brands by reducing errors and accelerating time to market.

ArtPro+’s comprehensive suite is built with the supplier’s needs in mind, offering tools that go beyond traditional object-based preflight checks.

It addresses the nuances of packaging prepress, from detecting thin parts and structural issues in folding cartons to ensuring accurate color-to-ink mapping in flexo highlights.

Addressing Quality Concerns

ArtPro+’s technology is precisely engineered to enhance quality across every stage of the prepress process.

With built-in advanced PDF editing technology, along with other tools for dynamic content management, text recognition, an integrated viewer, and an artwork approval connection (Share & Approve), ArtPro+ empowers prepress teams to:

- Ensure all content (text, graphics) is correctly positioned and distributed across packaging mediums.

- Verify the readability, spelling, and compliance of all mandatory and SKU-specific copy.

- Place machine-readable content, like barcodes, accurately according to technical specifications and standards.

- Guarantee content reproducibility with the designated printing process, thereby avoiding common pitfalls.

Streamlining Prepress for Success

By harnessing the power of ArtPro+, suppliers can confidently navigate the prepress landscape, ensuring that each packaging SKU exits the production line flawlessly.

This efficiency not only solidifies the supplier-client relationship but also dramatically shortens the time to market, setting a new standard for quality and reliability in packaging prepress.

Quality as a Cornerstone, Not an Afterthought

ArtPro+’s extensive feature set and Esko’s commitment to end-to-end solutions redefine what’s possible in packaging prepress.

For suppliers and brand owners alike, ArtPro+ is more than a tool; it’s a strategic partner in the quest for perfection, ensuring quality is embedded in every aspect of the packaging life cycle, from concept to shelf.

Change is the Only Constant

Continuously evolving and reshaping your business is essential to thriving in the next “new normal” — and beyond, whatever that may be.

Digital tools help future proof your business, allowing you to respond faster to unforeseen industry changes, ensuring you’re always prepared for what’s next.

Want to see our solutions in action? Watch a product tour here.