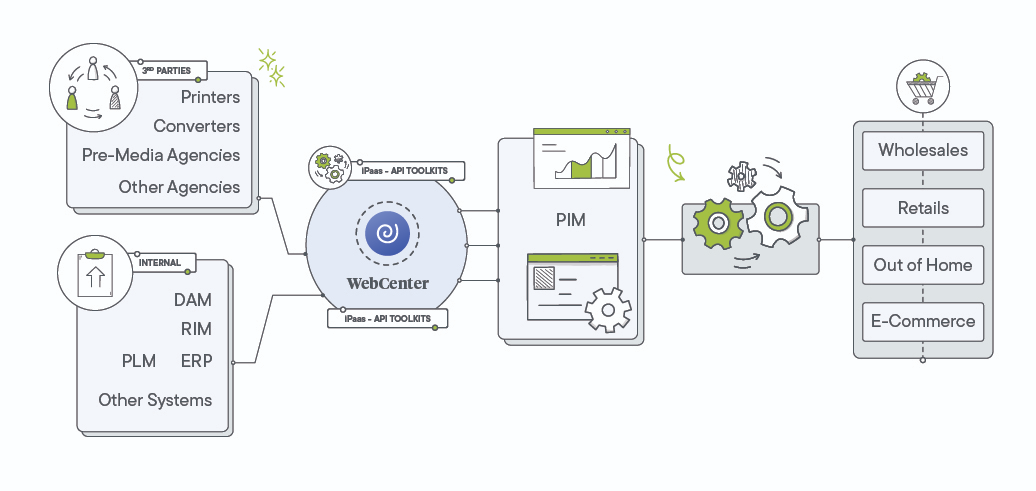

Imagine a world where your Artwork Management System (AMS) sits at the core of your content ecosystem, acting as the bridge between sources of truth and systems of record. With seamless integration across your PLM, ERP, and PIM systems, real-time, accurate data flows effortlessly, eliminating the need for manual content duplication. This vision drives the concept of operational excellence – streamlining every aspect of artwork management to improve efficiency, accuracy, and consistency.

Through these integrations, businesses experience significant operational efficiencies, leading to shorter turnaround times and optimized workflows. Additionally, content is synchronized across both digital and physical shelves, ensuring brand consistency and compliance across all product offerings.

Can you picture it? We did.

An AMS can become the heart of your partner ecosystem. By integrating it with your data lake or reporting tools, you gain real-time insights to make informed decisions, improve processes, and manage vendor performance. This streamlined system is the foundation of operational excellence, ensuring your artwork management processes are future ready.