Regulations regarding sustainability and packaging are, at best, a moving target. New regulations are being introduced while current regulations are continually being updated. Sustainability regulations are very nuanced and staying compliant is no easy feat.

The Ecodesign for Sustainable Products Regulation (ESPR), Packaging and Packaging Waste Regulation (PPWR), and Corporate Sustainability Reporting Directive (CSRD), are but a few examples of such regulations. Let’s take a look at each one.

ESPR came into effect on July 18, 2024. It is a key component of the European Commission’s strategy to promote sustainable products as well as their circularity. The regulation addresses how the EU’s consumption contributes to climate change and pollution and how to minimize their effects. As part of the 2020 Circular Economy Action Plan, ESPR is designed to help the EU meet its environmental and climate goals, improve energy efficiency, and double the circularity rate of material use by 2030.

PPWR, expected to be implemented in the near future, aims to reduce the environmental impact of packaging across the EU by promoting waste reduction, reuse, and recycling. Key measures include setting specific targets for packaging reduction, mandatory reusable packaging systems for certain sectors, and stricter recycling requirements. The regulation also seeks to reduce over-packaging, improve the recyclability of materials, and harmonize packaging laws across EU member states to ensure a unified approach to sustainability.

Among other things, PPWR will require that every package is designed to be recyclable by 2030. It will also impact labeling, the use of plastics, and additional packaging information.

CSRD expands the scope and requirements for sustainability reporting. It requires companies to provide more detailed information on how their operations impact the environment, society, and governance (ESG).

CSRD applies to a broader range of companies, including large and listed small and medium-sized enterprises (SMEs), and mandates that reports be audited for accuracy. The goal is to enhance transparency and promote sustainable business practices across the EU. This regulation seeks to standardize sustainability at a federal level, something that’s never been done before.

According to Jan De Roeck, Marketing Director of Industry Relations & Strategy at Esko, “Business that are not preparing for this new reality today, run the risk of losing access to certain markets tomorrow. This is a particularly important change compared to previous years. The avalanche of new regulations makes business leaders nervous, and uncertainty about what needs to be done by when creates the risk of delaying investments. Expect trade associations to provide more clarity for their members in this forest of new legislative initiatives.”

It’s clear compliance is non-negotiable. Per Susie Stitzel, Director of Product Management at Esko, “Adapting to new regulations with recycled or recyclable materials is essential. Failing to do so could lead to non-compliance or unsellable products, which would result in significant losses to companies.”

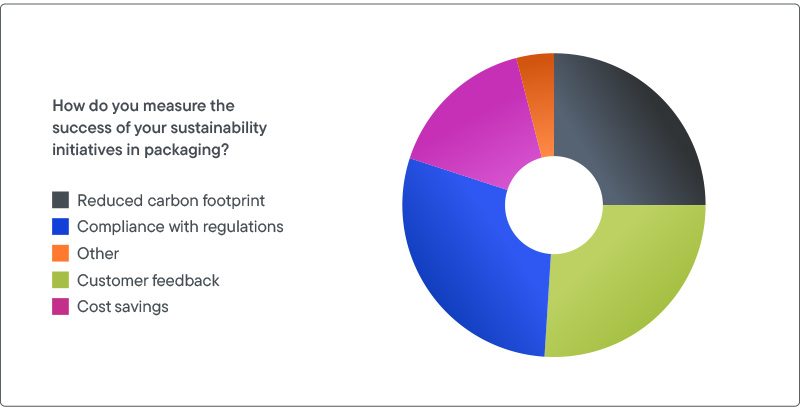

Furthermore, compliance with regulations is seen as a barometer of success, with the highest number of survey respondents agreeing they measure the success of sustainability initiatives by ensuring compliance with regulations.