We know how it is for busy packaging & label converters. More of your customers are demanding shorter runs, with faster turnaround times, putting ever more pressure on your prepress operation.

Not only do you have a whole host of files to be manipulated, checked and made consistent, but laying out those jobs in an optimal way is time consuming and can lead to press inefficiencies. Managing this increased workload is becoming more of a challenge.

We’ve been speaking with packaging & label converters across the sector, looking for the best way to help your prepress team handle this load, while boosting your digital press accuracy and output.

With recruiting to expand workforces or increasing shifts being among the more expensive options, the logical and economical solution is to implement a completely automated workflow.

The Perfect Automated Workflow

- Eliminates errors from the process by allowing users to preset repetitive tasks

- Allows for automated decisions in the workflow

- Increases efficiency and throughput

- Saves time and reduces cost as the workflow runs unattended, 24/7

Automate Prepress Tasks

An automated workflow serves as the heart of any packaging prepress department.

It consists of separate prepress and workflow tasks that work unattended, conducting many of the chores typically left for prepress operators such as preflight, trapping, repetition, adding registration marks, making reports and more…

Conditional Decisions

All these tasks are linked together in one workflow. Some tasks require conditional decisions that are based on preset parameters, while other decisions depend on management review and can be held until approved.

3 Reasons Why You Should Automate Your Prepress Workflow

1. The Highest Quality for Every Job

An automated workflow greatly enhances quality assurance. Operators, CSRs and admin staff can detect errors early in the workflow, increasing quality, avoiding expensive mistakes and reducing costs.

A Viewer for Experts

A good, automated workflow will contain a job viewer that displays a packaging job just before it is sent to the output device to produce plates or to be printed. An expert can check separations—even bitmap data, trim sizes, and differences between the original design and final production files, to make sure that all corrections have been made.

Compare Jobs

Automated ‘compare’ tools allow someone to see those changes instantly. Jobs can be held until someone in authority gives a green light to proceed.

2. All the Tasks to Get the Job Done

Perhaps one of the most beneficial facets of an automated workflow is that it performs many tasks that were previously performed manually by packaging production operators.

Some Examples

A packaging prepress workflow can automatically import PDF files from a customer and preflight them, assuring that they can be processed correctly — before they enter the workflow.

Edit Separations

Automated workflows can remap the inks of images or edit separations. It can define ink properties (varnish, opaque, technical), screen rulings and angles—including the dot shape.

Trapping

And, when artwork is nearly complete, workflows can automatically trap a job based upon a printer’s own specifications.

MIS Integration

Data can be acquired from an external database or MIS system to streamline and automate step-and-repeat or imposition tasks.

Generate Barcodes

Workflows can even generate dynamic barcodes with assured printability, offering advanced features such as automatic box generation, bar width reduction, and output resolution-dependent scaling.

Or they can create dynamic marks for proofing, printing — or simply registration marks.

3. Connect to Order Administrative Systems

Interfaces between order administrative systems (MIS or ERP) and prepress production further reduce manual interaction.

Seamless Integration

In fact, workflows integrate seamlessly with almost any business software system, accepting a wide range of desktop publishing formats, supporting RIPs or file servers and industry standards such as PDF, XML, XMP, SQL queries and JDF/JMF communication.

Job information and workflow parameters can be transferred automatically from the order admin or logistics systems, without any operator intervention.

Use Job Metadata

Data can include step & repeat info, barcodes, inks required, and more.

Workflows can also extract job metadata—offering an automatic link to order ID, due date, customer info, customer service rep (CSR) contacts, and more.

How to Automate Your Prepress Workflow

With comprehensive support for mixed printing processes, Esko Automation Engine sets up an automated prepress workflow that ensures faster throughput, greater flexibility, more uptime and improved quality of output without duplication of efforts.

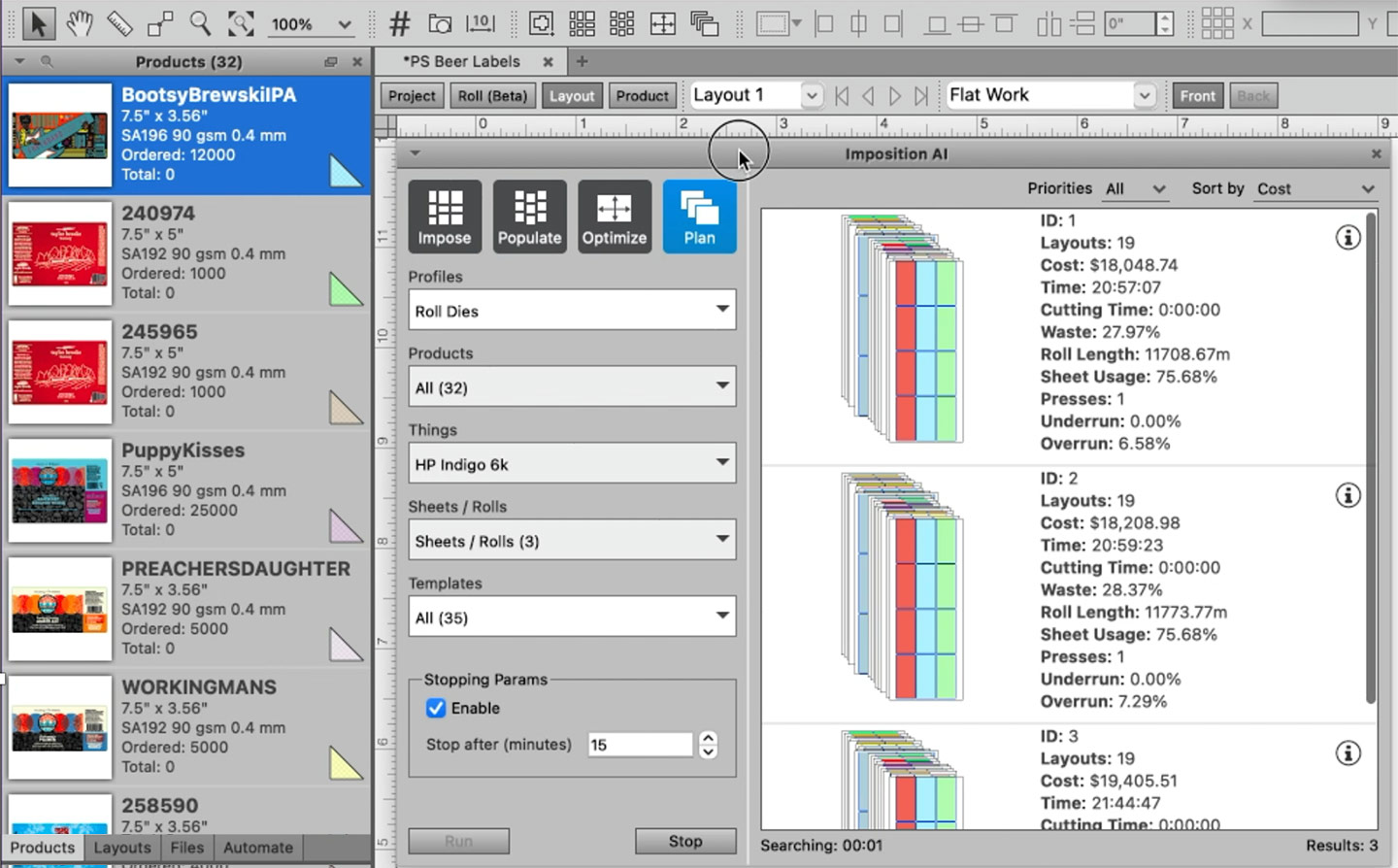

For example, our unique algorithms create optimal layouts to make the most of your press.

Color Preflight increases efficiency by allowing operators to use the most efficient ink set and reduce unnecessary downtime.

While Dynamic Variable Data Printing (VDP) software, designed specifically for applications such as labels, delivers an easy way to create and work with VDP jobs on a digital press.

Automation Engine not only automates production tasks but also integrates business systems to speed up the overall process.

As it reduces the error rate and the need for operator intervention, it further increases efficiency and productivity too.

7 Ways to Improve Your Prepress Workflow With Automation Engine

You’ve done your homework and established that automating is the right move for you. Now let’s explore the ways you can enhance your workflow with Automation Engine.

1. Make Your Workflows Smarter

Use Job Management to automatically create jobs and efficiently organize data storage and the job’s metadata, its link to order ID, due date, customer info and customer service representative contacts.

The benefits:

- Always use the most up-to-date file, factoring in updates is easy

- Save time spent searching for files

2. Get It Right First Time

Detect content errors on any file type prior to output with Viewing and QA. Compare versions of the same file, of different files, or between file types (screened, stepped) – there is even barcode scanning and braille reading.

The benefits

- Reduce product reprints – save money and protect your reputation

- Ensure a high-quality output – create consistency and standardize quality control checks

- Catch and resolve discrepancies automatically

3. Bring VDP to the Heart of Your Press

Make automation work for you by enhancing your digital printing solutions. Automation Engine works alongside your current tech stack, with extended support for VDP templates created in DeskPack or ArtPro+.

The benefits

- Easily bring VDP to the heart of your press – rather than keeping it as a siloed activity which is more exposed to error.

- Save time – the required expansion of data sets can be offloaded to automatically create individual PDF files for each of the variants.

- Reduce risk of error – stay in the same industry standard format all the way to the RIP, thereby reducing the risk of conversion-induced errors.

- Minimize manual intervention – eradicate manual management of sizeable VDP files.

4. Simplify Your Analytics

Create and customize easy-to-read job report cards and templates, which can be shared with your customer, and view your job in high-quality 3D.

The benefits

- Create reports automatically

- Share easy-to-read reports with your customers

- View your jobs in 3D

5. Automatically Step & Repeat

Streamline and automate the overall job processing by automating step & repeat. Impose or nest files for both conventional and digital printing, including variable data processing. The function supports labels, folding carton, corrugated, digital, commercial print, signage or display production, with data acquired from an external database or MIS system.

The benefits

- Reduce manual intervention

- Create predictable, repeatable, and data driven stepping

6. Check and Correct – Easily

Automate common error checks, ensure incoming files are processed in a consistent way and receive full reports generated ad hoc. You can also automatically perform more than 200 checks with Enfocus PitStop, which is fully integrated into Automation Engine.

The benefits

- Automatically check and correct your files

- Process your incoming files in a consistent way

- Generate full reports against checked files

7. Reduce Ink Consumption and Manage Colors

Benefit from centralized color management with ink saving tools and advanced color conversion tasks. The color functionality delivers a reduction of ink consumption and the most stable print quality.

The benefits

- Reduce press setup with automated conversion into a fixed-color set

- Reduce press downtime with less wash outs required between print runs

- Automatically convert from source to CMYK to destination CMYK

- Use Equinox to Convert spot colors to a fixed ink set e.g., CMYKOGV, and UCR, GCR

- Enjoy cost savings on ink and the ability to run multiple jobs on single press run

Automate today to work smarter, not harder, tomorrow. Stay ahead of the competition while improving efficiency and reducing costs.

Contact our experts to understand how you can automate your packaging workflow – book a discovery call today!