100% Quality Assurance for HP Indigo 20000 Digital Press

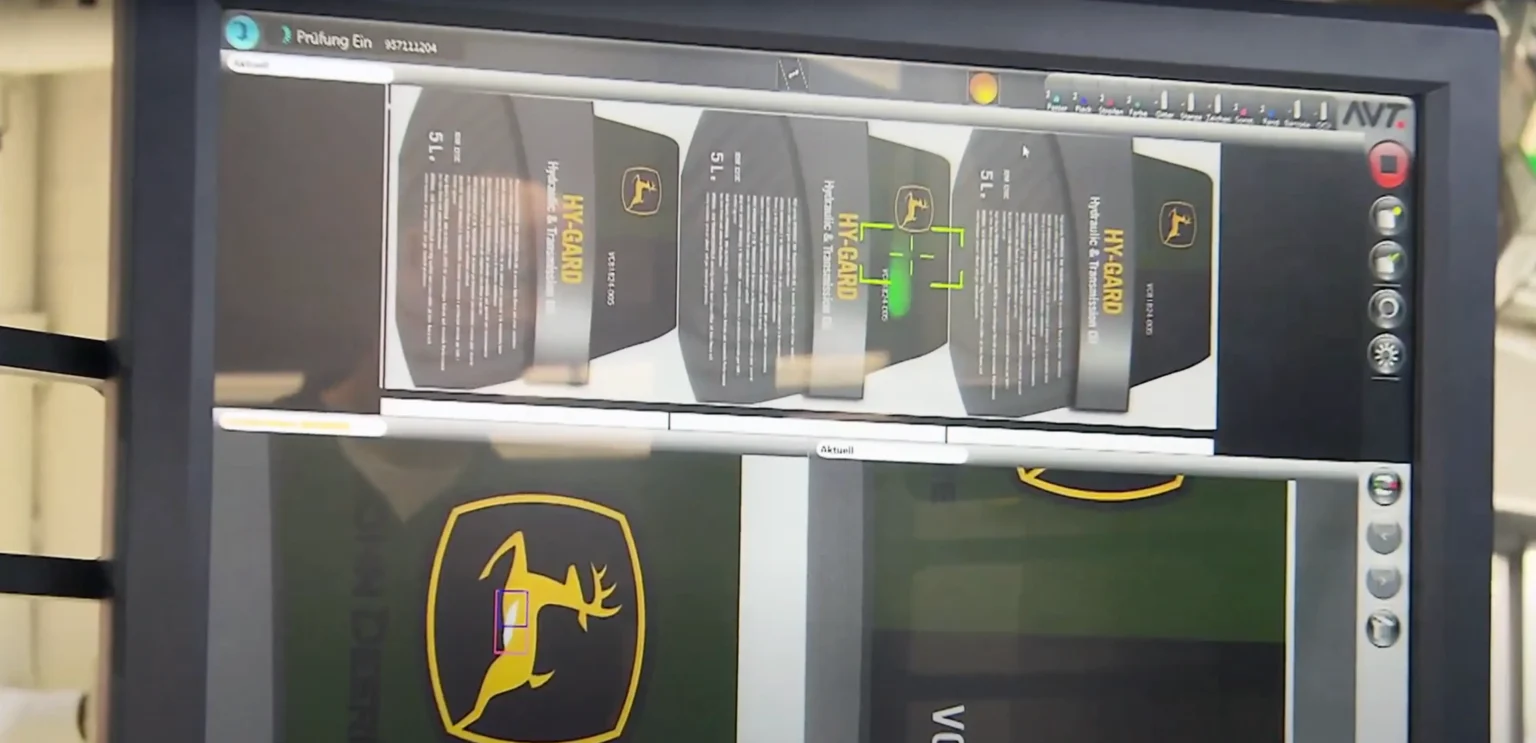

The system can be easily installed on the HP 20000 press to achieve online quality assurance and process control.

The system’s high resolution and high speed ensure print quality, data validity, barcode and number tracking, as well as DeltaE color monitoring – all in one pass!

How AVT Apollo 20k Works

AVT Apollo 20k detects a variety of print defects, including color variations, misprints, low contrast defects, mis-registration, spots, and splashes.

It visually indicates the precise location and type of each defect, while in parallel, the system records all relevant defect data into roll reports.

Real-Time Defect Detection

An easy to view color-coded light tower informs operators when a defect is detected, so that errors can be addressed and corrected in real-time. The system provides full process control and trend monitoring, in addition to a comprehensive quality assurance package.

Benefits of AVT Apollo 20k