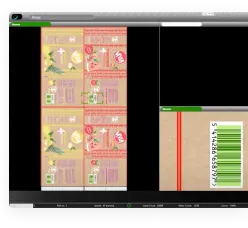

Automate Job Setup and Eliminate Manual Intervention

Streamline prepress to press room – automate and reduce job setup time on any sized print run.

Key Benefits of AVT AutoSet

AutoSet provides operators with confidence that the inspection system is properly set. It works smoothly, automatically sending job data from Automation Engine and making it available for the press operator to load and start inspection.

IT Manager, IPB Printing