100% Quality Assurance for Metal Sheet Decoration

AVT Titan is connected to your print production workflow, capable of triggering ejectors, marking devices or kickers to automatically mark/eject defective sheets.

The system can also connect to the press’s feeder to stop printing if a process defect becomes severe.

How AVT Titan Works

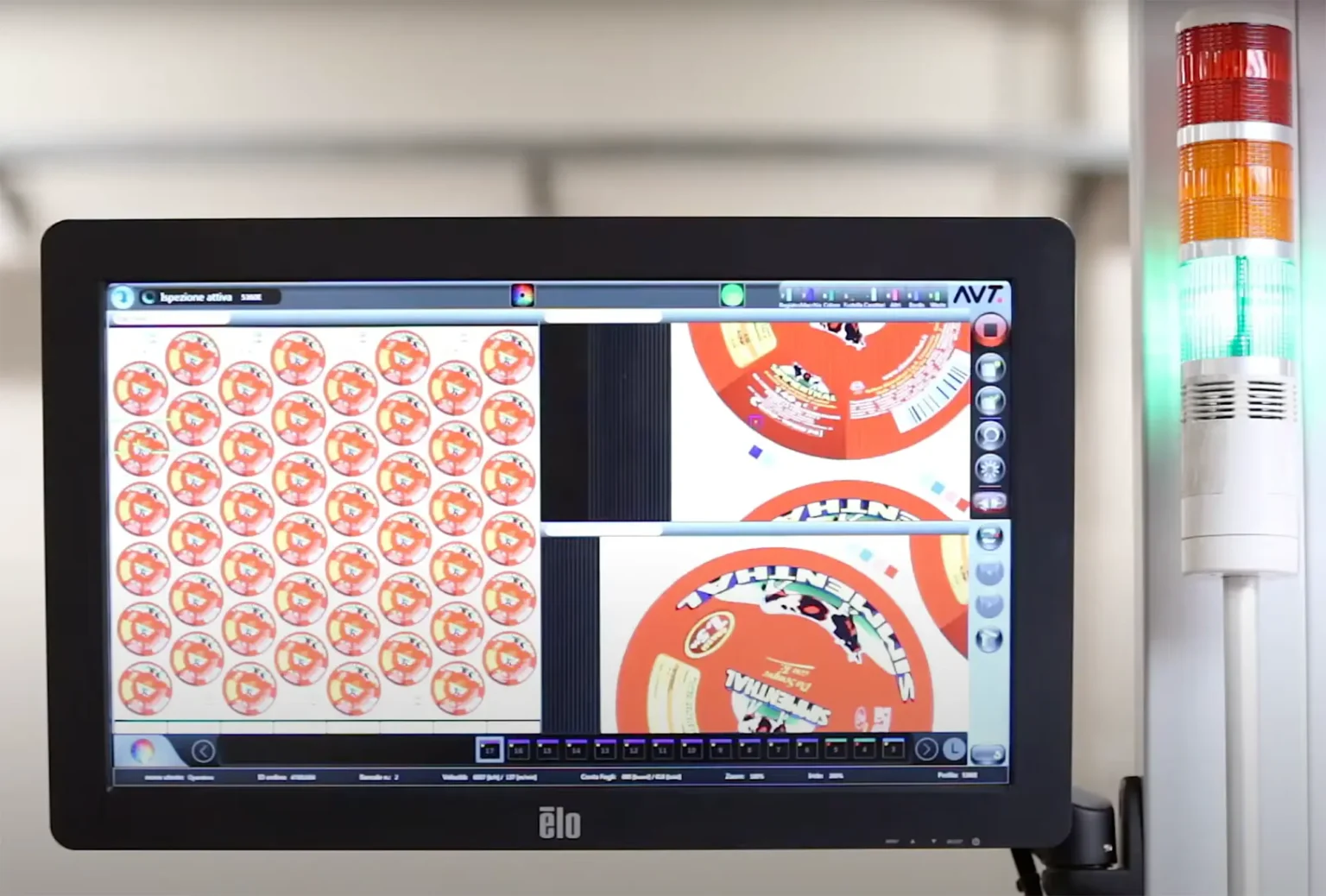

A colored alarm light tower alerts the operator immediately when a defect is detected, according to pre-defined quality thresholds.

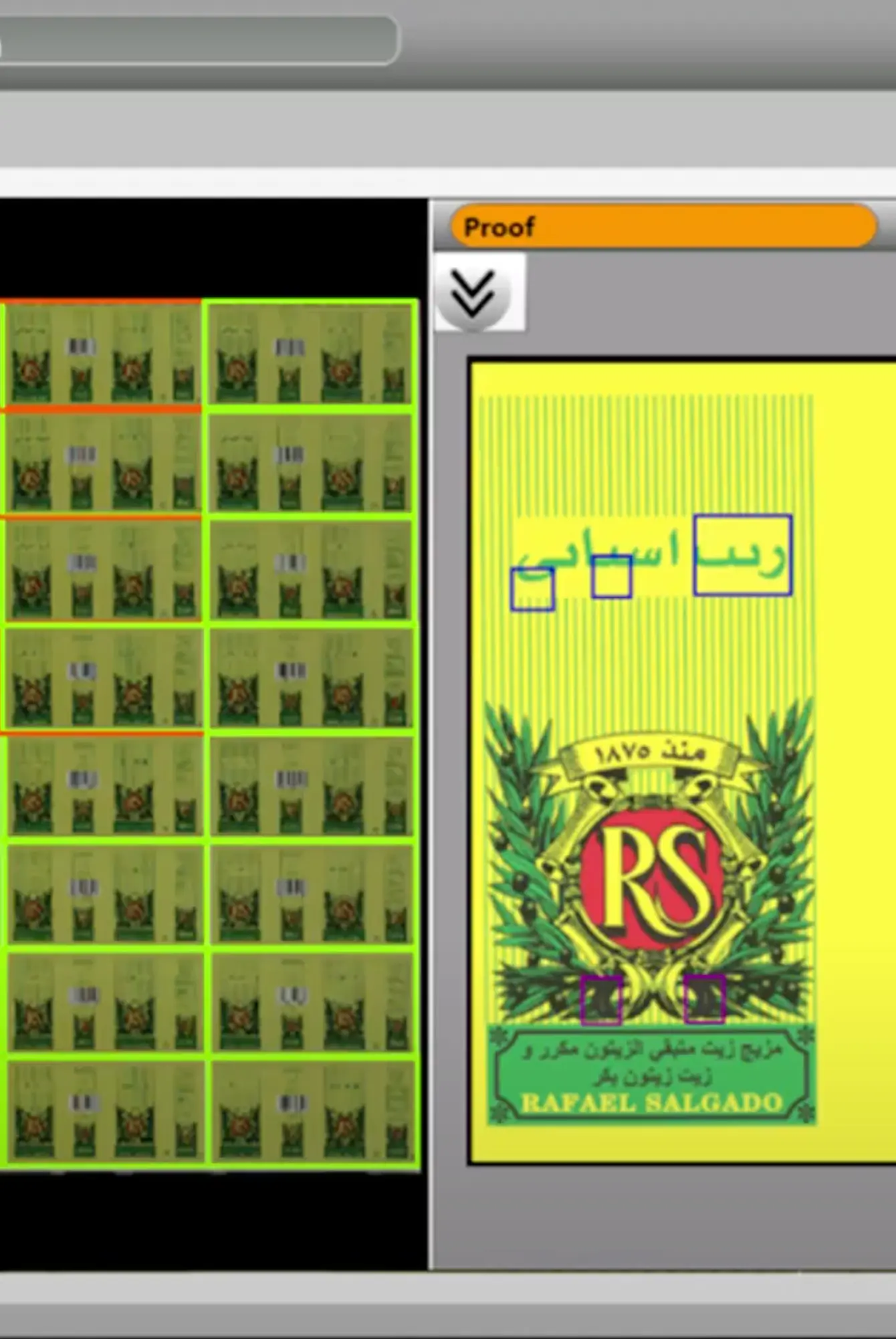

The system visually indicates the position and the nature of all detected defects on screen. The operator can then address the problem and correct the relevant defect.

Benefits of AVT Titan