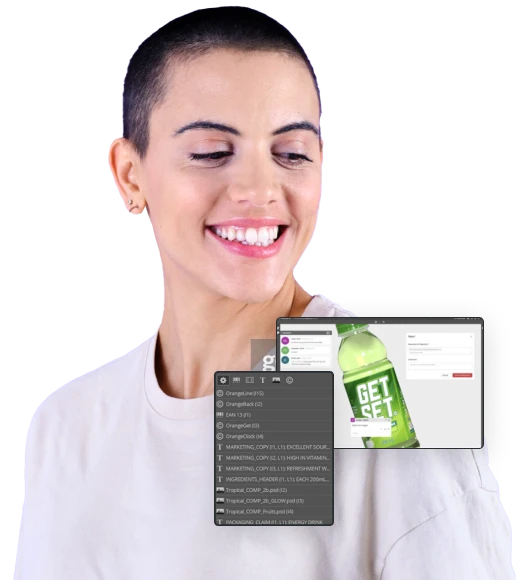

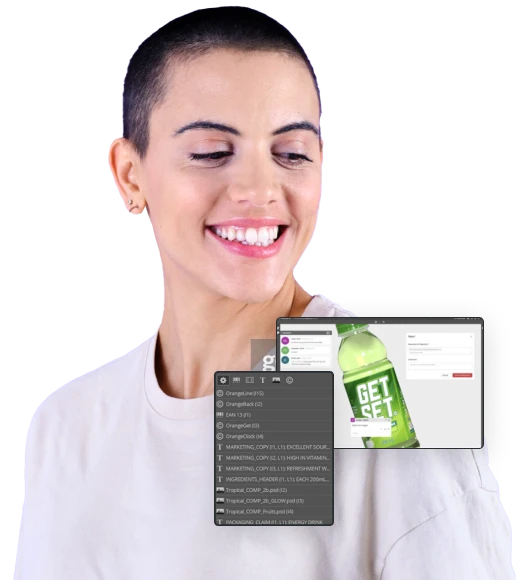

When American Fuji Seal automated their front-end process by slitting in-line, they removed the color bars traditionally measured in an off-line process. With this process change, they needed a different system to ensure color quality and consistency.

American Fuji Seal implemented Esko AVT SpectraLab XF. SpectraLab XF provides real-time in-line color measurement and monitoring, ensuring accurate color consistency throughout the entire print run and eliminating the need for manual off-line checks.

American Fuji Seal has two printing presses installed today with the AVT SpextraLab XF camera system. They’ll also implement a third machine, which will become operational in 2025.