Digital Finishing Was Becoming a Bottleneck Requiring a Fix

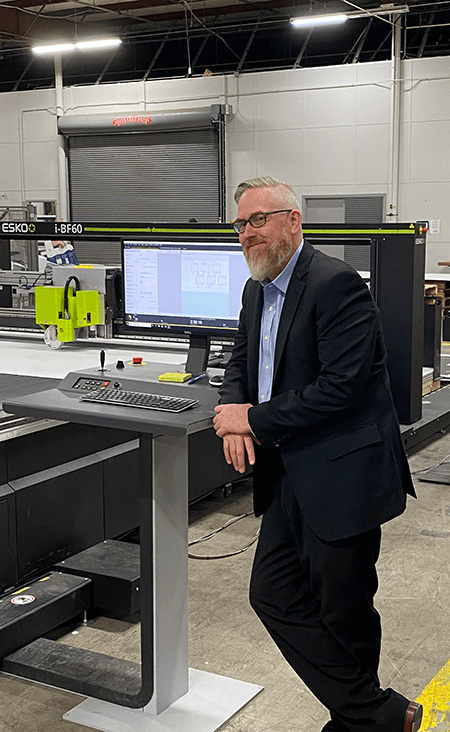

At CaroCon, we have a significant competitive advantage in that we are integrated right back into our own paper mills that are producing new, sustainable lightweight papers. These feed our corrugated plants and produce the corrugated board we use here at CaroCon,” said Craig Marsh, General Manager of CaroCon Display and Packaging.

“This integration gives us total flexibility in our supply to customers and the capability to respond quickly to changing customer needs. We’ve seen significant growth in short run and fast turnaround demands as retail competitiveness intensifies. Clearly, we’re now in a digital age and we have to respond to that trend.

“We’ve worked with Esko for over 15 years having relied on our Kongsberg DCM, as well as an XP hand loader for specialty materials. We’re running corrugated converting 24/7 and thanks to the auto-loading capability on the DCM, the business can run all night.

“However, up until our latest Esko investment, when we were printing single pass and finishing with a cutting die, we were finishing at the same rate as the print shop, so we could cope with the throughput. But when we were running digital production, cutting times are longer than our printing time and we needed three machines to each press to keep up with production. Digital finishing was becoming a bottleneck to maintaining our growth and service levels.

This integration gives us total flexibility in our supply to customers and the capability to respond quickly to changing customer needs. We’ve seen significant growth in short run and fast turnaround demands as retail competitiveness intensifies.

“We recognized that investing in more digital finishing capacity was the solution to optimizing our productivity and capacity challenges and looked long and hard at all the tables on the market. What we saw was that the Kongsberg C64 digital finishing table was designed for truly industrial scale production. It’s built for larger volumes and seemed more reliable and better quality for the price. It was therefore an easy decision for us.”

Integrated Hardware and Software to Boost Finishing Productivity and Quality

Prior to investment, a team of 5 operators would manage the digital finishing department per shift at CaroCon.

“The Kongsberg C64 combined with the feeder stacker and underside camera doubled our capacity overnight and enabled us to reduce headcount to 3 per shift,” said Craig.

“We have been running a Kongsberg DCM for over 15 years. Our guys are used to automatic loading and unloading, which has been great when we can leave it running over night or the weekend. They’ve also become very experienced in operating the equipment. It’s a great piece of kit but times have moved on and that machine only runs at half the speed of the new Kongsberg C64. This meant we still had to come in at weekends to load or unload.”

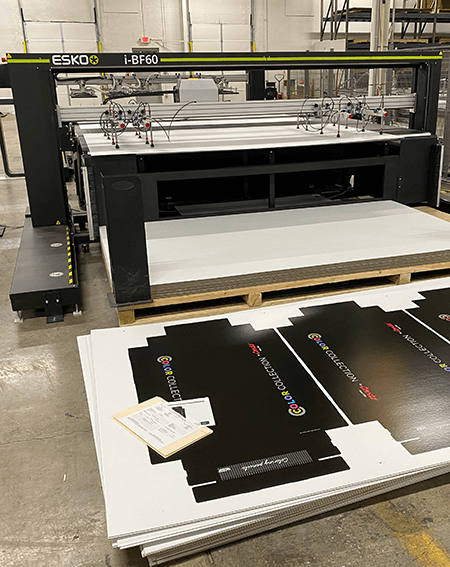

To boost its capabilities, CaroCon invested in a Kongsberg C64 with an integrated feeder stacker to increase loading and unloading productivity, along with a new Esko underside camera.

With a stack height of 915 mm/36 in and quick automatic load cycles, the Kongsberg C64 with feeder stacker and underside camera is the optimal solution for short run production on all typical packaging and display materials.

The underside camera investment enabled CaroCon to integrate its digital finishing processes in to the established Esko Automation Engine set up enabling scanning of sheets from below (the print side) and automatic location of registration marks, barcodes and the corner of the sheets. This automation would now save the company between 20 and 30 minutes per job set up.

“This was all new technology for us. Esko was great in helping us get started. We learned together how to integrate the technology into our Automation Engine workflow. We now just drop the files into the Automation Engine software, it puts the dots where they are needed, sends the file to the press and then table, which then simply reads the dots and cuts where needed. We just have to scan and pull the right code for the job. We’re really not doing a lot now but getting great results, faster!”

A Doubling of Capacity, Quality Enhanced and a Work/Life Balance Improvement!

CaroCon is primarily focused on corrugated conversion. “Over 90% of our work is corrugated and I can’t think of anything that the Kongsberg set up can’t handle, as long as there’s room on the sheet, of course.

“The biggest improvement we’ve noticed is that on the original Kongsberg DCM we had to nick everything, which is a very time consuming and a manual process. With the Kongsberg C64 feeder stacker, there is no nicking required. It’s easier to break jobs out after finishing and we’re creating cleaner parts, which our premium customers really appreciate. We’ve had great feedback on that.

“In high end cosmetic displays, for example, we need as many clean edges as we can get. High end packaging and display work represents about 25% of our throughput. Being able to provide tailored designs with our digital printing capability for regional pharmacies or drugstores, rather than relying on large volume national campaigns, which is how it used to be done, really offers a great solution for our customers with the quality that they’ve come to expect from us.

“We also didn’t expect one benefit which was that our guys no longer have to come into the department multiple times over the weekend. The teams used to have to come in a lot more with the DCM, but now they only need to come in once all weekend. We can run for 45 hours non-stop with the new feeder stacker. This has improved everyone’s work/life balance and with delivering clean stacks and edges, our customers are happy too!” concluded Craig.