The Challenge

Bringing Consistency and Efficiency Gains to a Growing Business

“In a business as busy and fast-paced as ours, it’s important that any of our teams, located anywhere around the country, can deliver a job in the same amount of time and operating to the same high standards,” said Sam. “So as the Reflex business continues to develop, it has become increasingly important for us to ensure the same efficiency-driving systems are in place wherever we operate.”

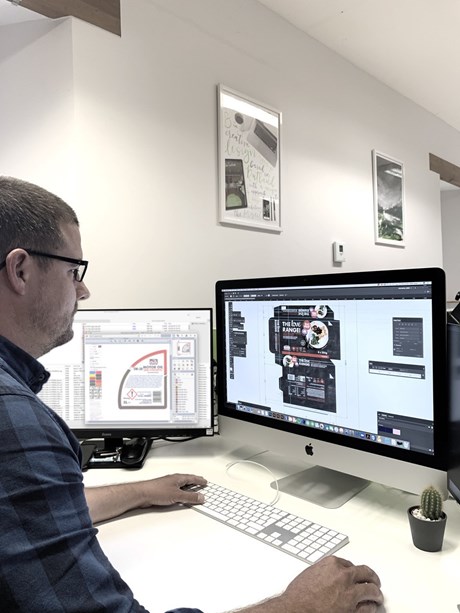

“Following that first installation, we’ve added Automation Engines at our other sites as the business has grown, either organically or by acquiring companies,” said Sam. “For example, we have gone into newly acquired businesses and have found a trail of paper being passed around with barcodes and job numbers, sometimes handwritten. In others, where there is a particularly high volume of work, we have had to thoroughly analyze whether we need to increase headcount to handle the level of throughput or if we can actually manage it better through improved automation.”

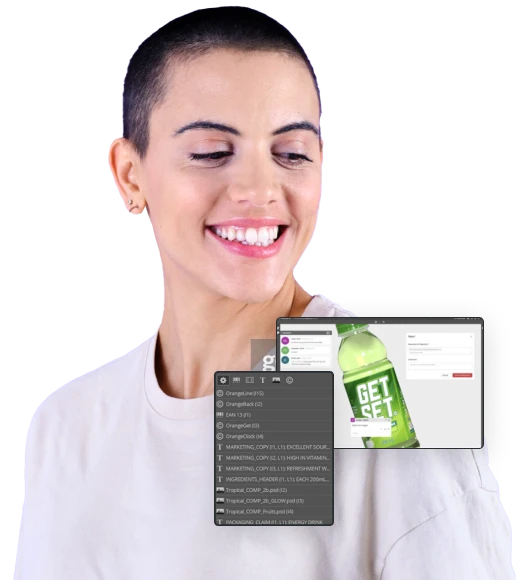

Sam said that as Esko Automation Engine not only automates print production tasks but also integrates business systems, it has helped to speed up the entire workflow process. “The combination of standardized processes and automated tasks helps significantly increase productivity, while the automated quality checks minimize errors and the need for operator intervention, bringing further efficiency gains,” he said. “When looking at it in those terms, Automation Engine almost gives us the capability of an additional operator.”

Not only does Esko Automation Engine seamlessly link between our various sites, but it is also the driving force behind our WebCenter.