Increased Productivity, Reduced Waste, Better Service

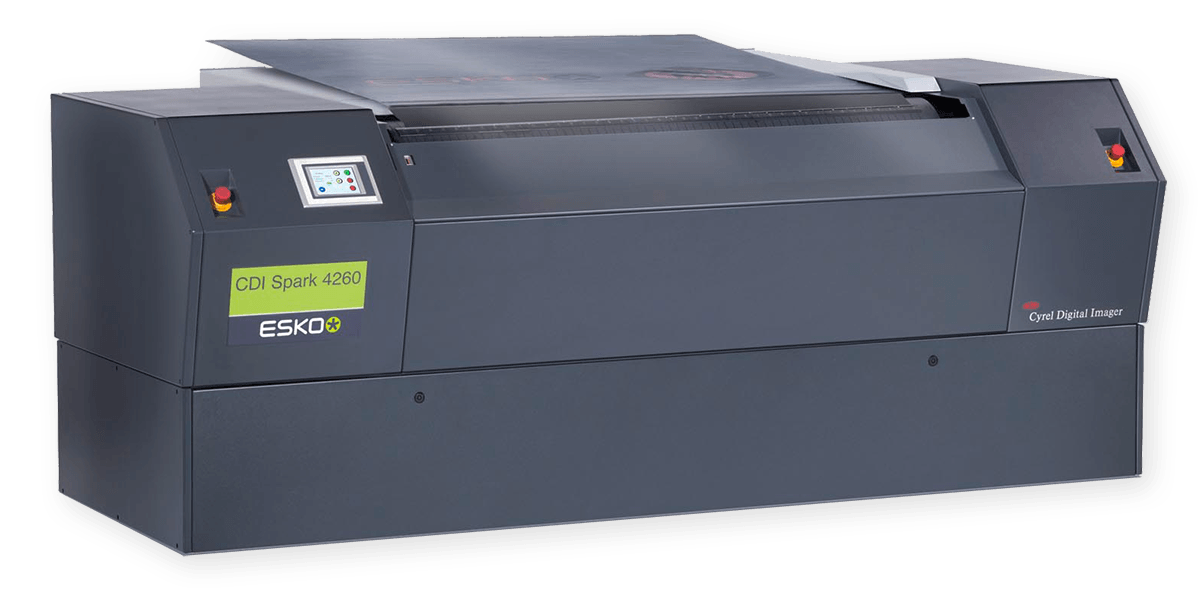

“This is our first Esko imager and we are delighted with the way the company helped us in the installation process despite being subject to lockdown restrictions,” added Mr Shingala.

He said that the increased productivity and reduced waste helped the company deliver a much better service to its customers, which proved particularly helpful during the challenging conditions faced during the pandemic. With this faster processing capability, Repro Poly Services is now able to meet the growing demands of customers based both in India and overseas.

“Our customers are obviously happy with a quicker service and improved quality,” said Mr Shingala. “Despite the challenges faced by everyone during the lockdown, we have been able to supply them the best quality plates on time.”

“We hope to serve our customers with the highest quality service for years to come thanks to the state-of-the-art technology that we now have at our disposal,” he said.