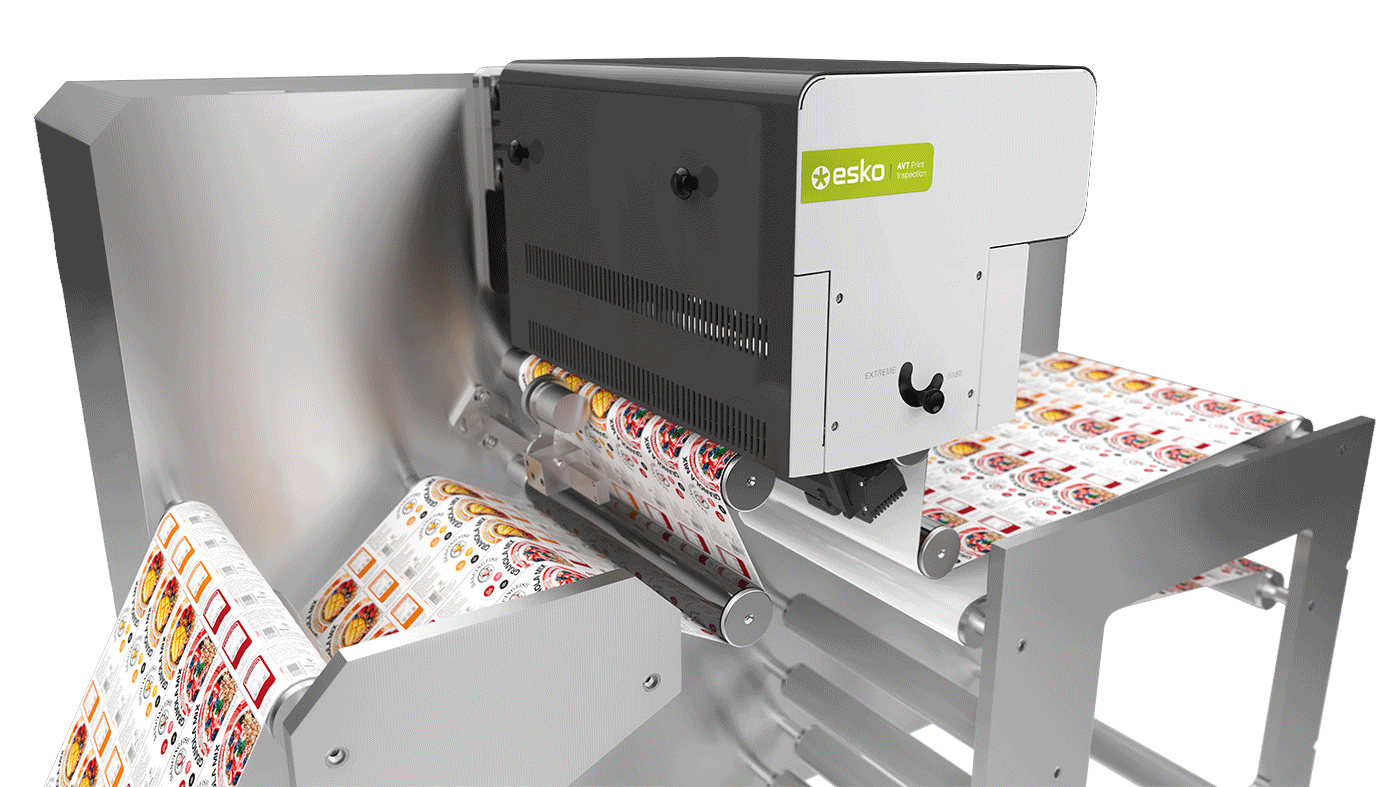

Add an Extra Layer of Precision to Your Current Inspection Setup

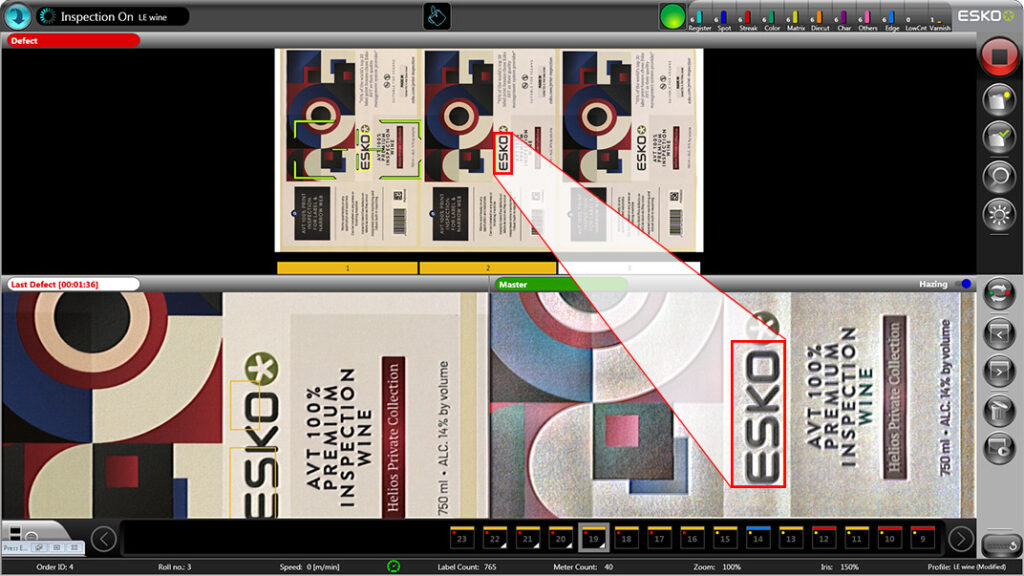

AVT Varnish Inspection uses state-of-the-art imaging techniques to analyze varnish coting layers. Proprietary algorithms identify imperfections and inconsistencies unseen by other inspection solutions.

Enable Viewing and Inspection of Varnish and Coating

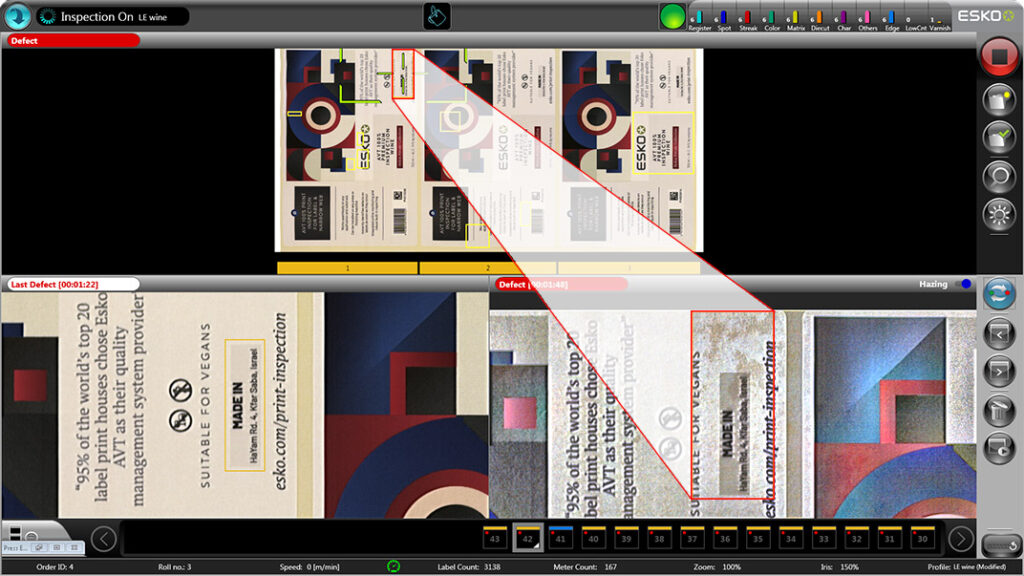

The Varnish Inspection Module provides inspection without the need to add UV sensitive pigments or any other additives to your varnish. Events such as varnish miss-register, partial starvation and full starvation can be detected simultaneously with the existing defect detection.