How a Large Folding Carton Converter Reduced Costs with Phoenix

Discover how a leading folding carton converter in the beauty, pharmaceutical, and cosmetic packaging sectors transformed its operations with Phoenix.

The Challenge:

Outdated technology and reliance on manual labor impeded the company’s ability to maintain profitability in short-run packaging.

The Solution:

Phoenix, a cutting-edge software that enabled the company to nest CAD designs with a single click, optimize press and sheet sizes, and generate comprehensive cost reports.

The Benefits:

Phoenix’s AI algorithm analyzed the most cost-effective ways to reduce expenses and decrease press time by combining items, evaluating overruns, and optimizing press forms to maximize efficiency.

Case Study Summary

A large folding carton converter operating in the over-the-counter beauty, pharmaceutical, and cosmetic packaging sectors is dedicated to fostering innovation and promoting sustainable packaging practices. Boasting a substantial turnover of approximately 80 million US dollars, this company manufactures over 3,000 unique cartons per month through manual planning processes. Recognizing the need to lower expenses and enhance operational efficiency, they implemented digital solutions.

In pursuit of these goals, the folding carton converter turned to Phoenix.

The Challenge

Limited technology and human constraints hindered the client’s efforts to maintain their profitability for short-run packaging. Layout creation was a manual and time-consuming process. With shorter runs and faster turnaround times being their current reality, the trial-and-error method of human planning was eating away at their margins.

For instance, the client would have what they called a “combo day” once a week, where they would gather cut samples and place them on press sheets for the best fit. They would then staple or tape the samples onto a larger sheet and deliver the layout to the CAD department for production files. However, the client managed 500 unique SKUs and a minimum of 100 production jobs per week, making this 24-hour process inefficient at best.

The Solution

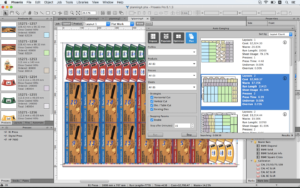

The company turned to Phoenix, which enabled estimators and planners to nest CAD designs with one click, determine optimal press and sheet size, and report press and material cost. Phoenix allowed prepress operators to drag and drop artwork to impose CAD layouts, auto-snap to artwork CAD dielines, and decorate forms with production marks. This minimized bleed overlaps and allowed them to export files into industry standard formats.

Phoenix’s AI technology enabled the company to import files with SKUs to auto-plan across multiple sheets. Automated impositioning helped manage the volume of SKUs by automatically taking graphic files and populating them on the CAD dieline. Phoenix’s AI algorithm evaluated the best ways to reduce costs and decrease press time by combining items, analyzing minimum and maximum overruns, and auto-computing press forms based on the most cost-effective, optimal way of running a particular batch of items.

Stepping into the Future

Phoenix enables faster, smarter, and more calculated decisions for shorter runs. Before Phoenix, the company spent 24 hours per job planning, 8 hours per job in CAD, and 1 hour per layout to impose. After implementing Phoenix, this converter reduced job planning time by 22 hours and took their layout creation process from 1 hour to 20 minutes! Items per sheet went from 2.1 to 2.5, which, when spread out over the sheets, resulted in $70,000 of net change over savings per month and 337-hour of capacity on press that was freed up.