In this blog, we highlight key takeaways from the webinar and expand on how packaging professionals can respond proactively to these evolving requirements.

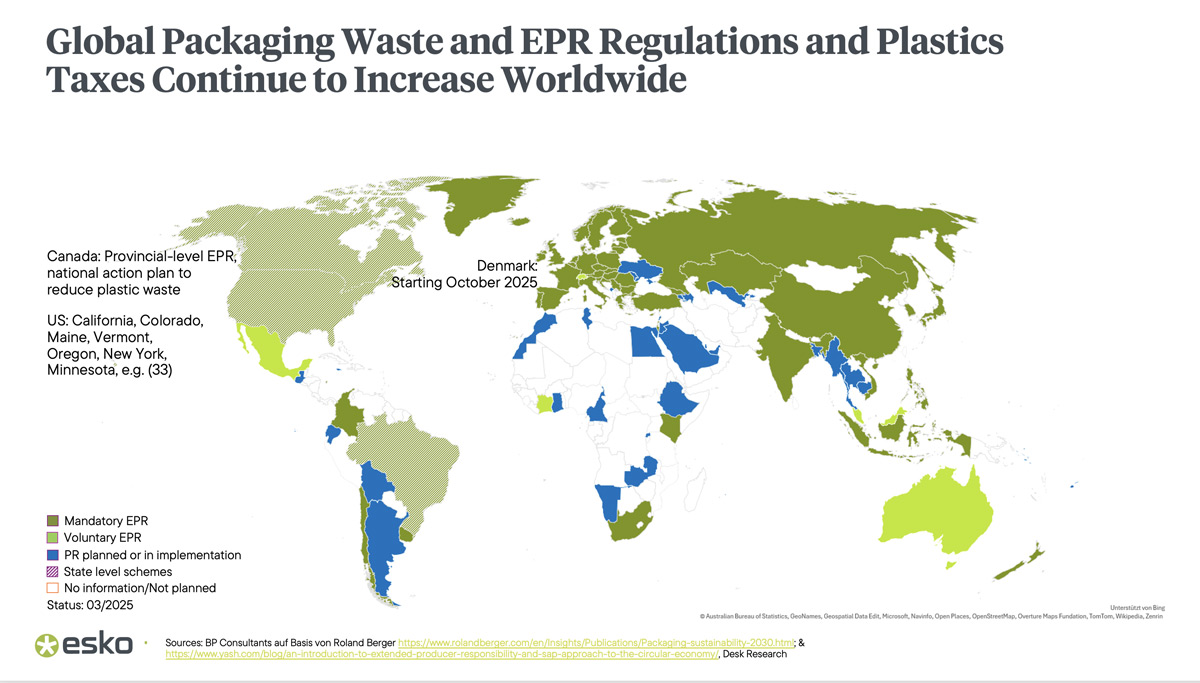

The surge in sustainability regulations reflects a global push to tackle the growing problem of waste as well as to foster a more circular economy.

In fact, global municipal solid waste volumes are projected to double by 2050.

This has resulted in a significant increase in packaging-related legislation globally, including the rise of Extended Producer Responsibility (EPR) systems and plastic taxes.

Health and safety are also paramount, with bans and limitations on single-use plastics and substances of concern (SoC) like PFAS becoming increasingly common.

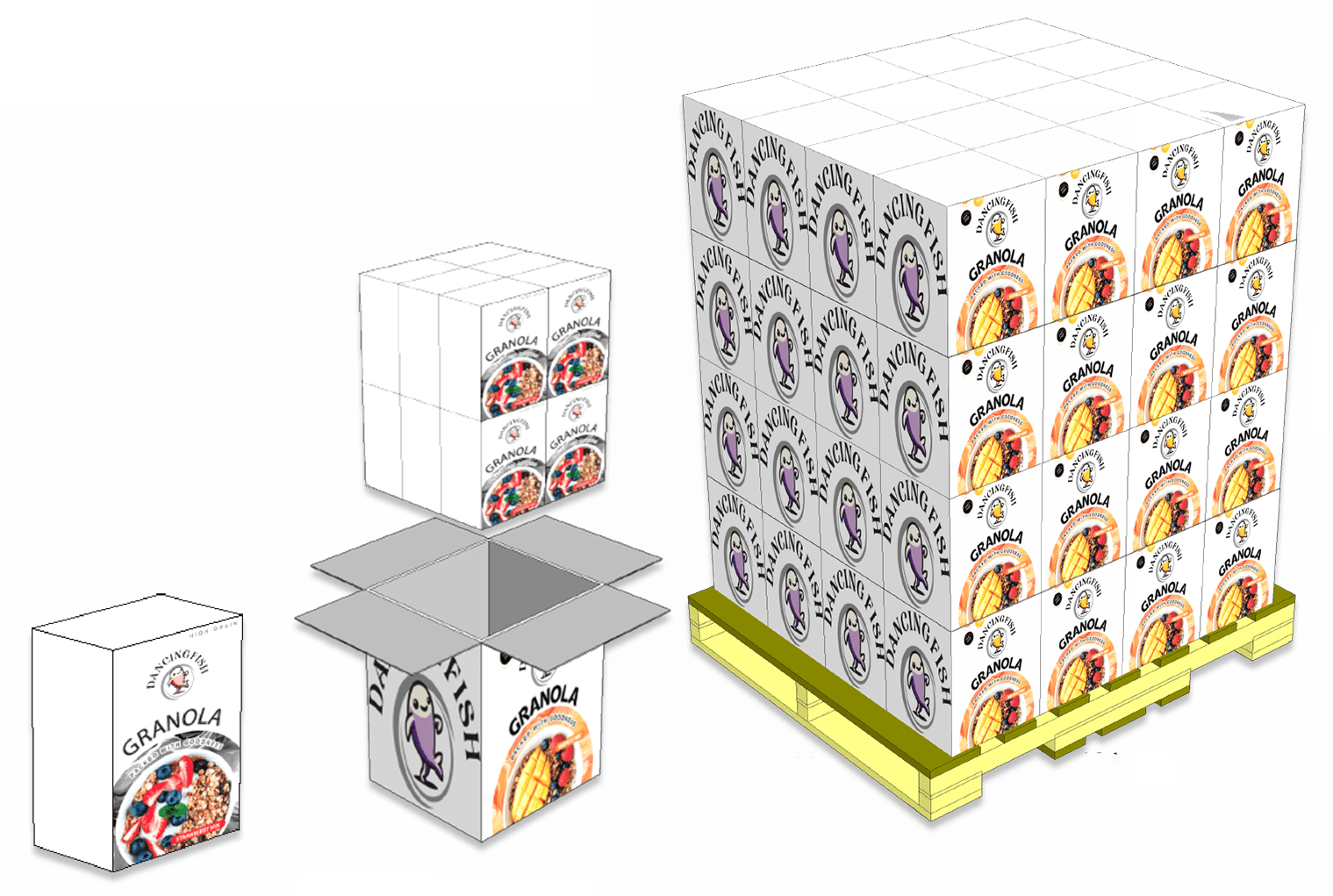

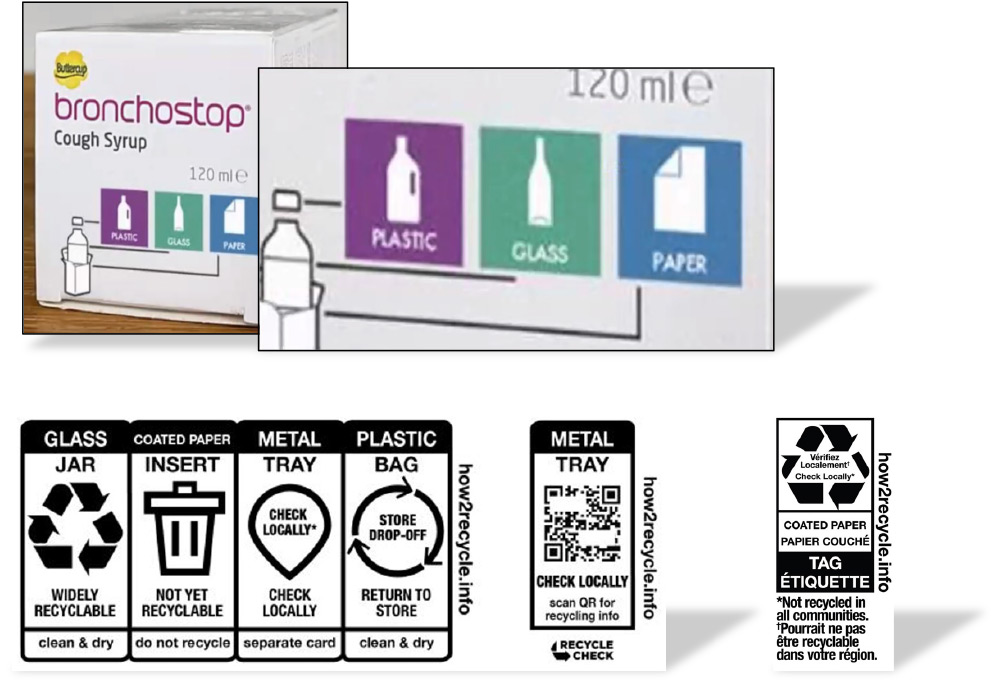

The focus of these laws is clear: reduce waste and over-packaging and foster a circular economy by emphasizing recyclability and the use of recycled content, especially in plastic packaging.

While compliance is necessary, aligning with these regulations also presents a strategic business opportunity—meeting growing consumer demand for eco-friendly products, improving brand reputation, and achieving cost efficiencies through material and energy savings.

It would be an understatement to say the regulatory landscape varies across different regions. For instance:

North America (US & Canada)

While there isn’t mandatory federal packaging legislation in the U.S., states like California, Oregon, and Maine have implemented their own Extended Producer Responsibility (EPR) laws.

Canada has a national action plan to reduce plastic waste, with provinces like Ontario and British Columbia implementing their own EPR programs.

This fragmentation presents a challenge for companies operating across different jurisdictions.

Asia/Pacific

Regulatory momentum is growing, with a focus on health and safety. China has introduced recycling targets and banned non-degradable packaging. Japan maintains a sophisticated system, while South Korea, Australia, and India are advancing laws around waste management, recycling targets, and mandatory recycled content.

Europe

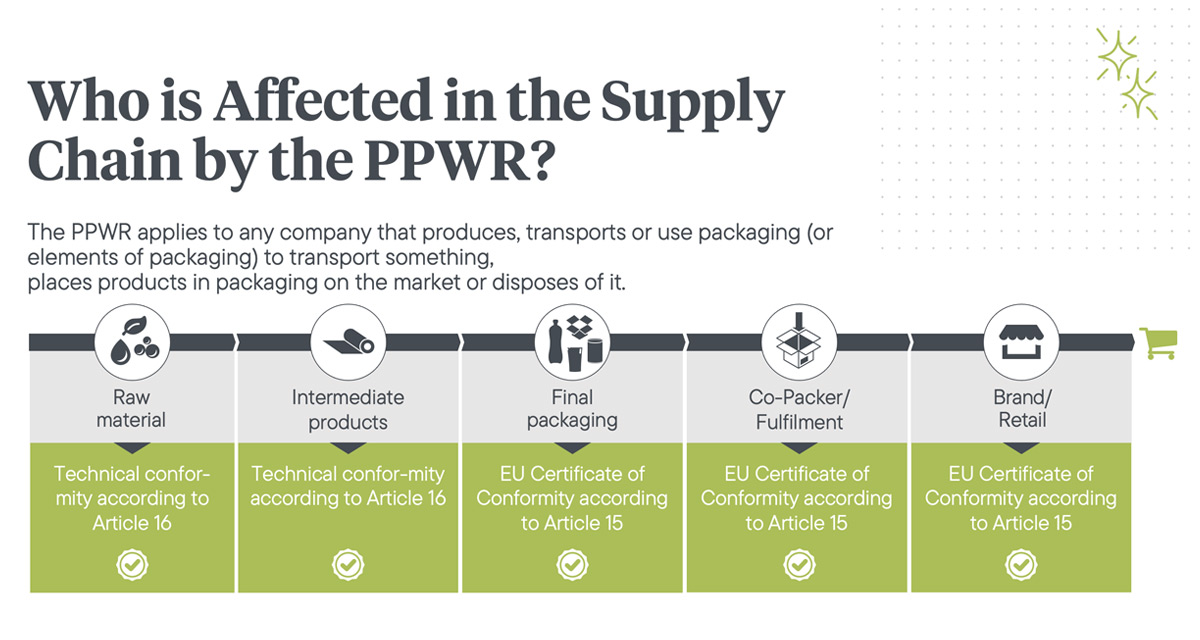

The PPWR regulation will be effective on August 12, 2026. It aims to reduce overpackaging and empty space, promote recyclability through design for recycling and restrictions on SoCs, and harmonize labeling and EPR systems.

This will impact the entire supply chain from raw material producers to brands and retailers. The first major impact will be the technical conformity assessment required for all packaging by August 2026.

Key targets include recycled content quotas for plastic packaging and reuse targets for various applications starting in 2030 and 2040. It also introduces sustainability reporting obligations.

These packaging regulations also impose sustainability reporting obligations. However, collecting and organizing accurate sustainability data remains one of the biggest challenges for companies. As a result, many are turning to digital tools to streamline data collection, aggregation, and management.