Packaging goes through a lengthy lifecycle before it reaches the consumer. And though there’s plenty to deliberate at each stage to ensure the product, in its beautiful packaging, reaches the consumer exactly as the brand intended, this is arguably the most important of them all.

Having made it off the store shelf, the consumer is in a position to decide if the product is something they’d buy again, recommend to a friend, or take the time to recommend on an online platform.

Recent trends see YouTubers and influencers in the thousands posting videos of the ‘unboxing’ of products, and commenting on the finish, feel and functionality of the packaging. Does it feel flimsy, luxurious, sturdy, etc.?

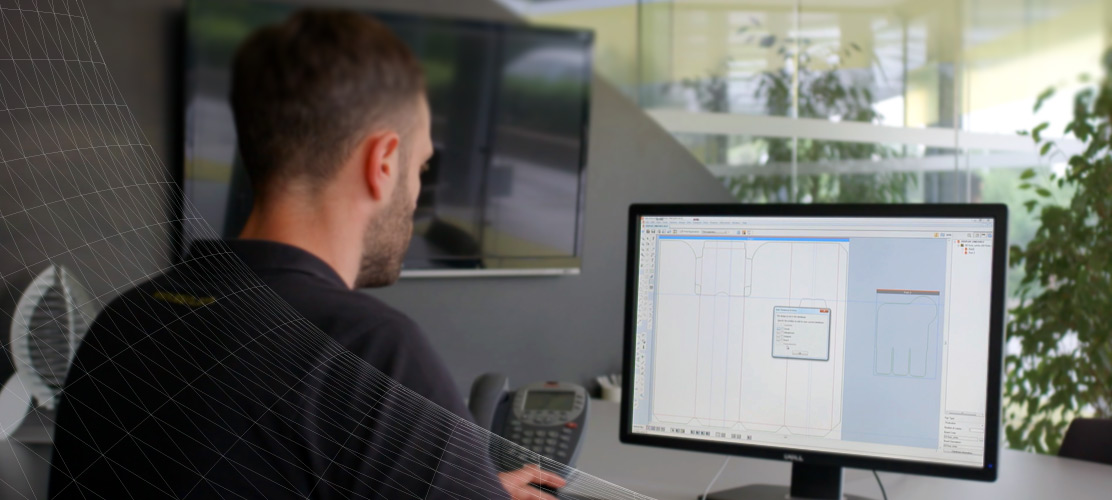

They address how the packaging opens and reseals, as well as how easy it is to access the product inside. Of course, all of this is important to every consumer (with or without a YouTube following). But, with packaging today being given such a vast platform, there’s more pressure on structural designers to impress.

Aside from looking and feeling great – the packaging must also have a safe and inclusive design, particularly for pharmaceuticals.