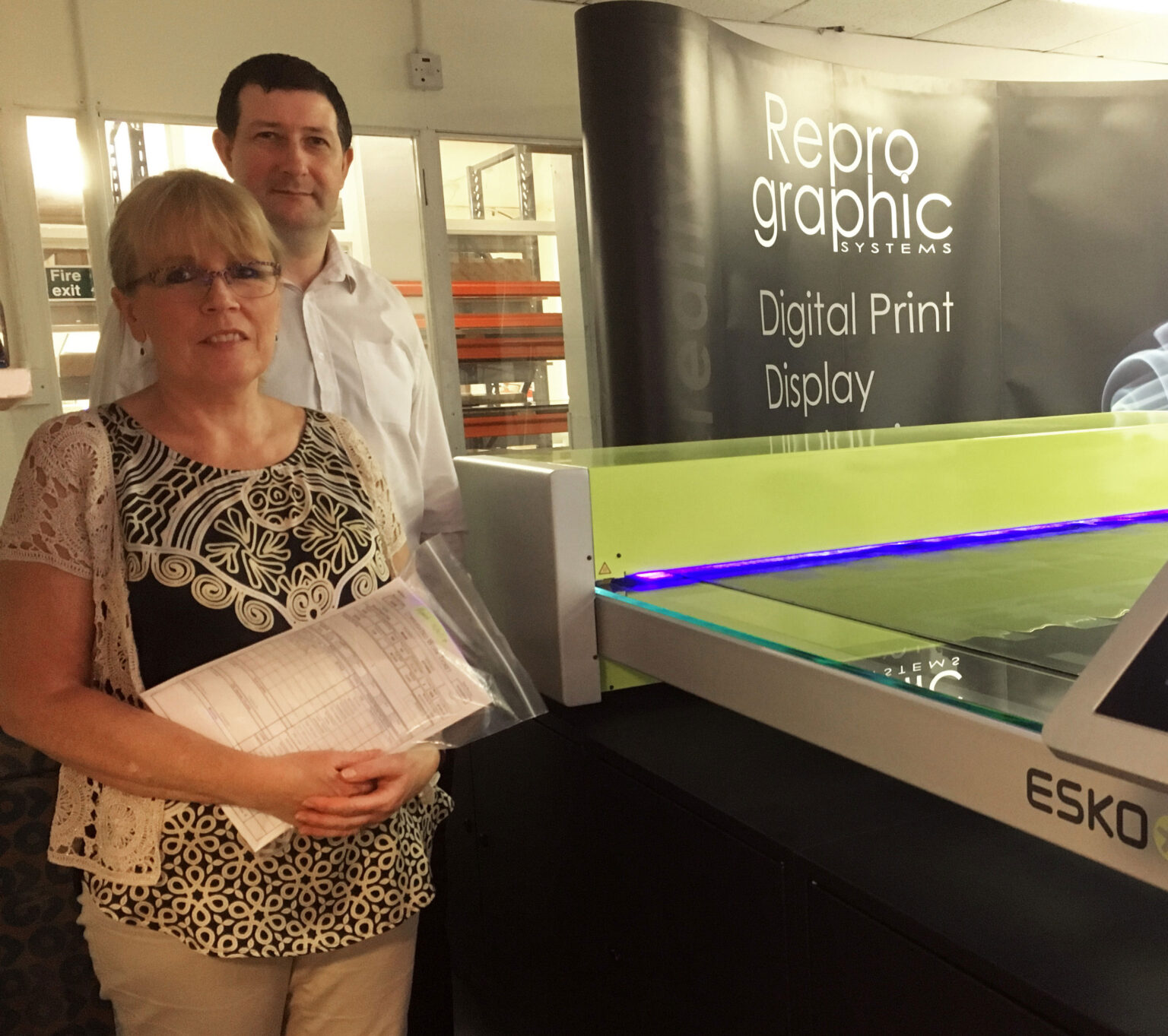

Reprographic Systems Wins New Business with Esko’s Crystal Technology

The award winning XPS Crystal exposure device provides Reprographic Systems with highly consistent flexo plates of the highest quality.

The Challenge:

Expanding business.

The Solution:

Confidence in a tough market

The Benefits:

Servicing the widest customer base.

Case Study Summary

Founded in 1969 in Dublin, Ireland – and in the mean time located at 3 different production sites – Reprographic Systems has become the market leader when it comes to prepress print services, catering the entire British Isles.

A long-term user of Esko solutions, Reprographic Systems believes in automating the entire production process, from front end to dispatch, as a key driver for growth.

Ghent (Belgium), 19 June 2017 – Esko, the global leader in integrated hardware and software solutions for packaging brand management, design and prepress, has installed the first XPS Crystal 5080 exposure units at Reprographic Systems in Ireland. The company has also invested in two of the latest Kongsberg Digital Finishing Cutting Tables plus Esko WebCenter software.

Paul Vaughan, Managing Director at Reprographic Systems says, “We are taking competitive advantage and winning new business. This important investment is a natural progression. We have been waiting to complete our digital solution with Esko’s new exposure technology. From front end to dispatch, Esko’s continuing commitment to innovation is exceptional and groundbreaking.”

The new XPS Crystal is a digitally controlled exposure unit providing near simultaneous exposures supporting all major photopolymer flexo manufacturers. As part of a complete automated platemaking system linking to a CDI imaging unit, the XPS Crystal 5080 offers a superior plate capable of printing at the highest quality levels on diverse substrates. One of the primary factors influencing plate stability is UV exposure, which is fast and holds the finest lines and text onto the plate. Full automation is achieved by linking the XPS to the new fully automated CDI Crystal and thus reducing the process from five manual steps to just one.

Vaughan explains, “The positioning of our three sites offer us the widest customer base. Thanks to these Esko solutions, we are now ideally positioned to service both economies in Ireland and the UK. In 2015 we jointly acquired Promopack Digital Studios in Heanor Derbyshire to extend and expand our reach. We know our future is secure with this investment. With the innovative Crystal technology from Esko we will increase our plate making production levels and improve our export capabilities. We have used Esko equipment since the early 90s. It is tried and tested and always delivers. For labels, folding cartons, and flexible and corrugated packaging we use Esko’s broad array of flexo tools and solutions. Our long term supplier relationship with Esko gives us every confidence in a tough market.”

James Mason, Esko UK/EIRE Sales Manager states, “Over the years we have established a strong relationship with Reprographic Systems and this latest round of investment has come through deep understanding and a detailed analysis of their needs and future aspirations. It is rewarding to know they continue to regard Esko as their partner of choice when it comes to ‘joined up’ innovation.