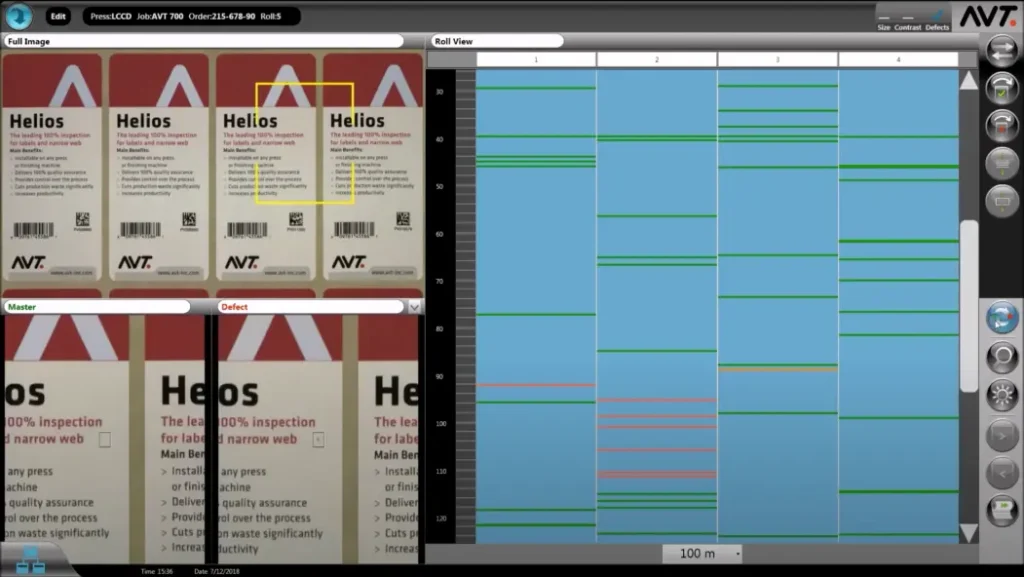

100% Automated Inline Inspection for Label and Narrow Web Printing

AVT Helios is a market-proven, automatic 100% inspection solution for labels and narrow web printing that ensures quality by identifying defects instantly on labels or packages, minimizing waste, and enhancing overall performance.

How AVT Helios Works

AVT Helios auto-detects various defects, such as missing labels, color variations, miss-registration, and more, offering superior inline quality assurance. Easily install on presses, rewinders, and other finishing equipment, supporting a wide range of machines, speeds, widths, and technologies.

The Benefits of Automated Inline Inspection