Better Plates Deliver Better Results

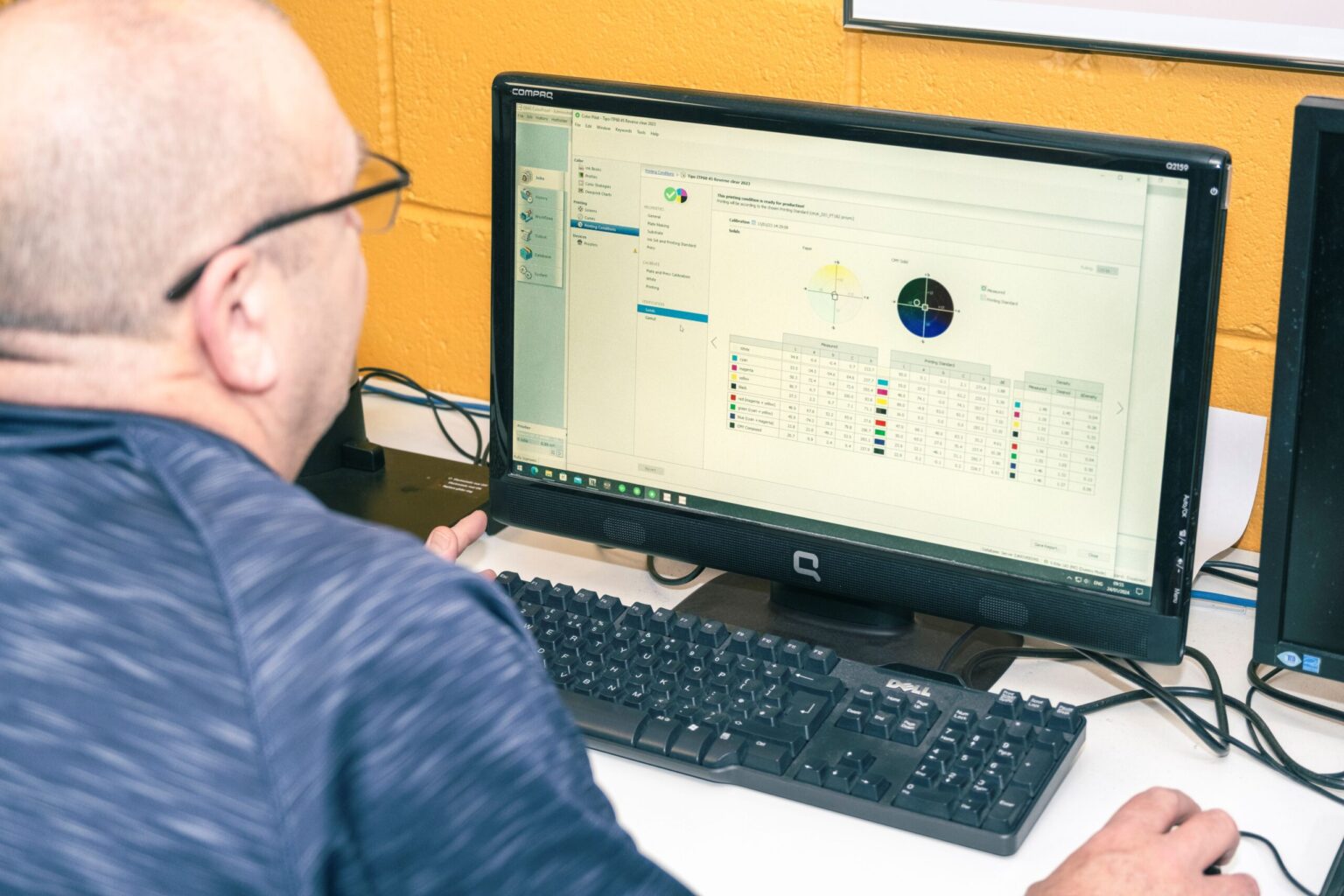

Rivendell uses a full ecosystem of Esko prepress software in its reprographics and platemaking, from Automation Engine, DeskPack and WebCenter through to Imaging Engine, Flexo Engine and Print Control Wizard with its Crystal screening.

“We use pretty much every bit of software from Esko in our prepress,” explained Lee Jones, Head of Graphic Systems at Rivendell.

With Crystal screening, we’re able to offer the best quality product. This means printers get better ink laydown, better white coverage, much better solid color, transition of highlight dots and so on. The overall quality is just massively improved.

“We have our own in-house platemaking facility, equipped with Esko 5080 CDI Crystals as well as XPS Crystal exposure units,” said Lee. “We started using Print Control Wizard around four years ago, and as recently as the end of 2023 we began using PCW for Corrugated.”

Gary Dawson explained that Rivendell prides itself on being at the forefront of technological developments in the industry, and so the team was quick to see the benefits of Crystal screening. “Then when our customers hear about it, they are keen to see the difference it gives to their plates and the final print quality,” he said. “With Crystal screening, we’re able to offer the best quality product. This means printers get better ink laydown, better white coverage, much better solid color, transition of highlight dots and so on. The overall quality is just massively improved.”