How Print Control Wizard Works

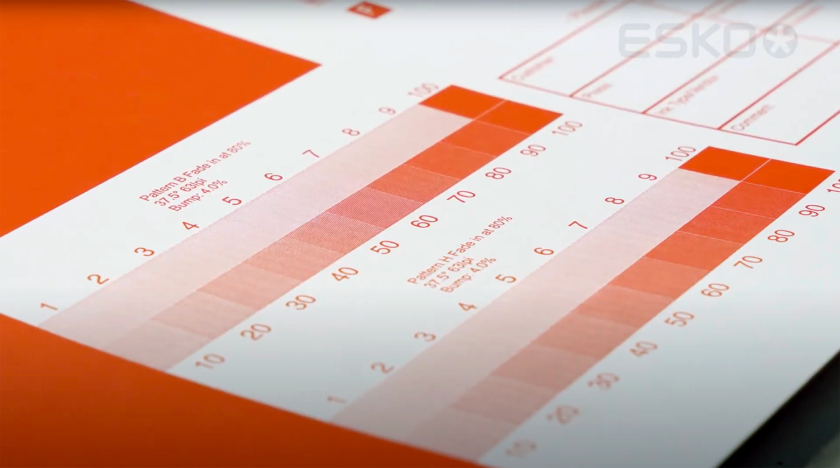

The tool uses all critical print parameters and variables to standardize the generation of Crystal Screens and curves for each application, removing all non-valued added tasks from the process.

A More Intuitive Plate Preparation Process

Built on Esko’s expansive flexo expertise, Print Control Wizard guides you through the plate preparation process and automatically creates new Crystal Screening for Esko’s Imaging Engine to rip the file before sending the separated LENx files to the CDI flexo imager and XPS Crystal exposure unit.

Print Control Wizard Benefits for Corrugated

Print Control Wizard reduces press stops for plate cleaning and make ready times. It also enables printers to move to fixed palette printing due to the consistency the software brings on platemaking.

Featured Resources

E-Book

2026 Packaging Trends

Learn more

Case Study

With Print Control Wizard’s Crystal Screening, Rivendell Manufactures “Perfect Plates that Deliver Perfect Results” for Packaging Customers

Learn more

Case Study